Production

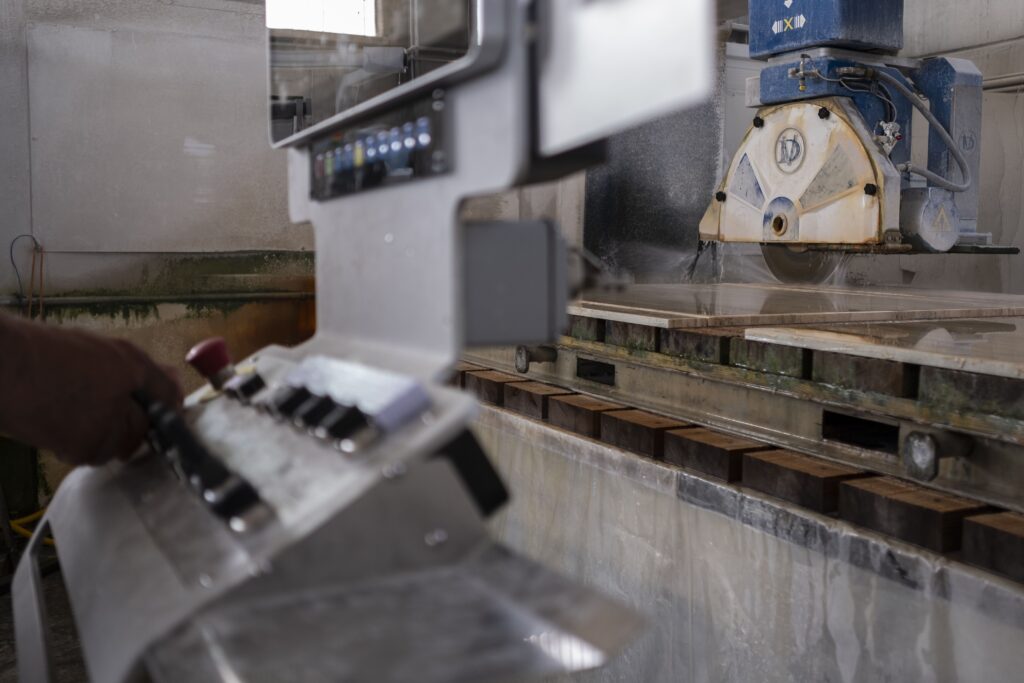

The production process is carried out entirely in our workshops. This gives us an important advantage as it allows us to control quality and precision in every work phase and compliance with the required delivery times.

We are committed to all aspects of the production process: from choice of the material in terms of beauty and strength to transformation of the block or slab into the finished product, from packaging and transport to installation and maintenance, to conserve the product in the long term. We have been called the “marble goldsmiths” because for each of us, whatever the production phase, meticulous attention to detail is fundamental.